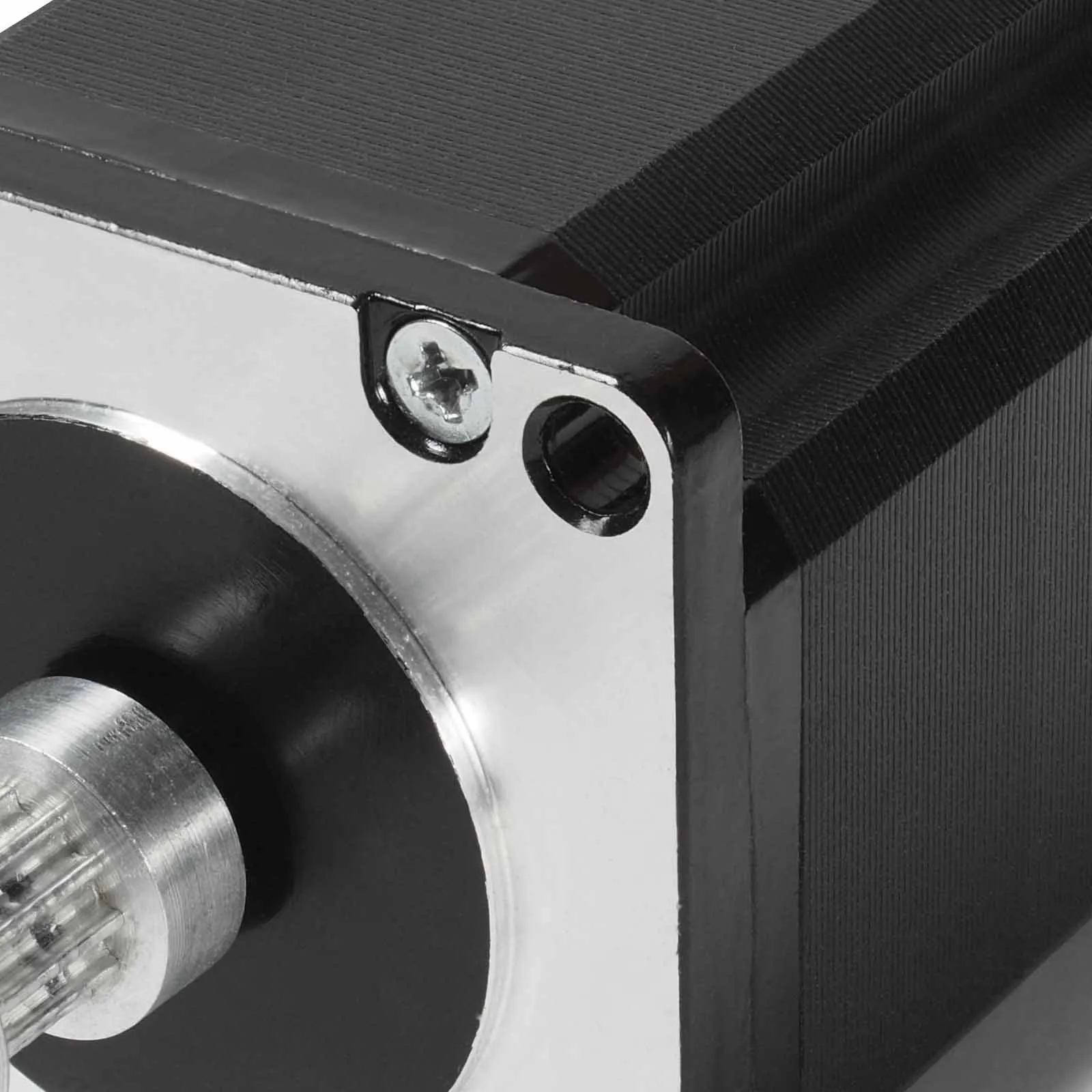

The stepping motor, also known as a stepper motor, is a versatile electromechanical device that converts electrical pulses into precise mechanical movement. It is widely used in various applications requiring controlled and incremental rotation or linear motion, such as robotics, automation, 3D printing, CNC machines, and more.

Key Characteristics and Features:

1. Precise Positioning: Stepper motors move in discrete steps, providing precise control over position and rotation. Each step corresponds to a fixed angle of rotation, allowing for accurate positioning and repeatable motion control in both rotary and linear applications.

2. Open-Loop Control: Unlike traditional motors, stepper motors operate in open-loop control systems, meaning they do not require feedback sensors to monitor position or speed. Instead, they rely on the precise timing of electrical pulses to determine the motor's position and movement.

3. High Torque at Low Speeds: Stepper motors generate high torque output even at low speeds, making them ideal for applications requiring high holding torque or static torque. This characteristic enables stepper motors to maintain position without the need for external brakes or locking mechanisms, enhancing their suitability for positioning and holding applications.

4. Bipolar and Unipolar Configurations: Stepper motors come in two main configurations: bipolar and unipolar. Bipolar stepper motors require a bidirectional current flow to drive the motor, while unipolar stepper motors use a combination of current switching to achieve rotation. Each configuration offers distinct advantages in terms of performance, control, and compatibility with driver electronics.

5. Full Step and Microstepping: Stepper motors can operate in full-step or microstepping modes, allowing for finer resolution and smoother motion control. Microstepping divides each full step into smaller increments, enabling more precise positioning and reduced vibration or noise during operation.

6. Driver Electronics: Stepper motors require specialized driver electronics to control the timing and sequence of electrical pulses sent to the motor windings. These driver circuits translate digital signals from a microcontroller or motion controller into the appropriate current levels and waveforms needed to drive the motor.

Overall, the stepping motor offers a combination of precision, reliability, and versatility that makes it a popular choice for a wide range of motion control applications across various industries. Whether you're building a robot, a 3D printer, or a CNC machine, the stepper motor provides the performance and flexibility you need to bring your projects to life.